Other sectors

The sectors listed above are just a small selection from our client base. We also coat components, for instance, that are used in:

- The automotive industry

- Fire protection

- Ultra-pure water production

- Rubber moulding

- Healthcare

- Petro chemistry

- Etc.

Related coatings

Solutions

Frequently asked questions

On request Kersten coating technology provides technical support to select the correct coating. We also advise you on the construction and finishing of the products to be covered. The most important points of attention have been incorporated in our construction guidelines and dimension regulations. We will send them to you on request or you can download them directly.

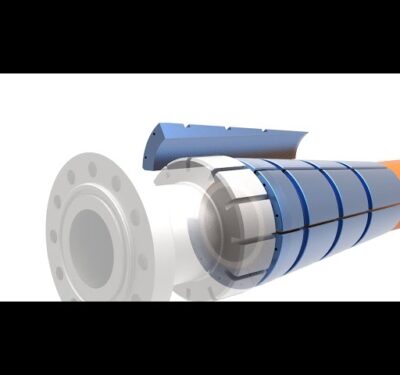

The plastic coatings are applied in our production in Brummen (NL) or in Kahla (D) using thermal processes. The parts to be coated are heated in indirectly fired ovens, after which the coatings are applied. The coating techniques we mainly apply are:

- Fluidized bed coating

- Electrostatic powder spraying

- Rotomoulding

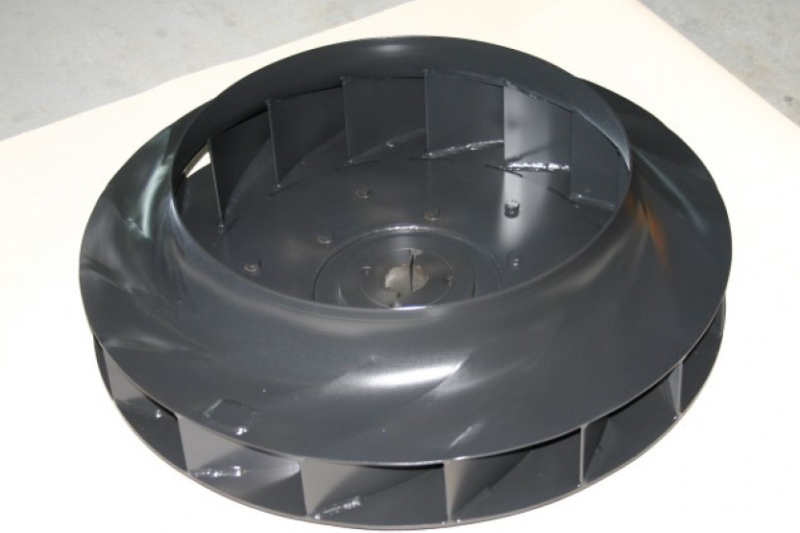

Some examples of markets that use our plastic coatings are:

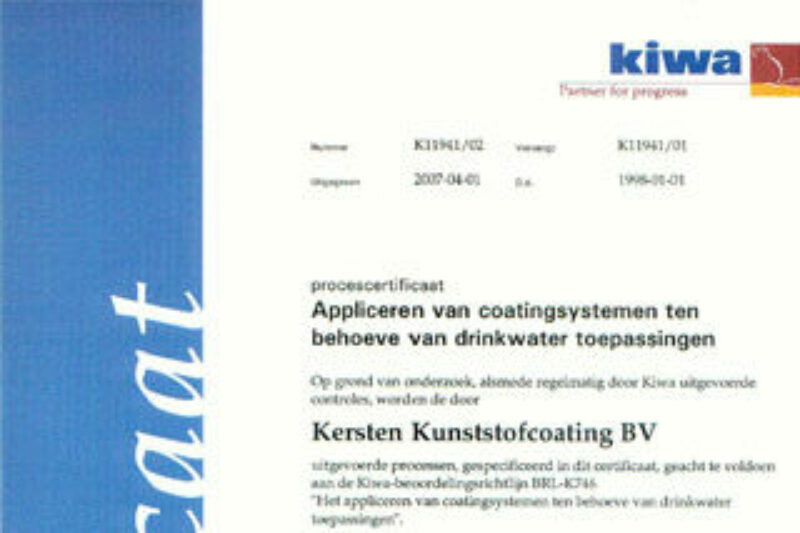

- Drinking water market

- Waste, sewage, and cooling water treatment

- Ship-building

- Printing

- Mechanical engineering

- Food industry

- Galvanic and semiconductor industry

- Process and chemical industry

- Automotive industry

Kersten applies plastic coatings using thermal processes. The main coatings are:

- Rilsan®, biobased Nylon 11

- Resicoat®, epoxy

- Halar®, Fluoropolymer ECTFE

- Xylan®, Fluoropolymers, PTFE, FEP and PFA

- Other Fluoropolymers including ETFE

- Abcite®, thermoplastic